Solution with LS-OPTui

https://www.lsoptsupport.com/examples-4.0/subpages/metaforming/solution-with-ls-optui

https://www.lsoptsupport.com/@@site-logo/LS-Opt-Support-Logo480x80.png

Solution with LS-OPTui

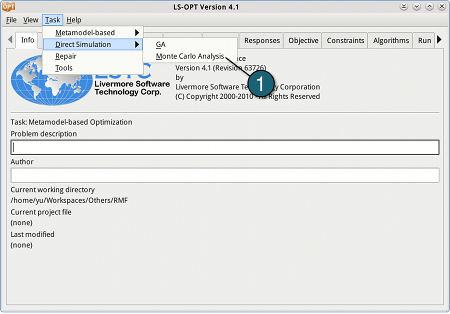

Monto Carlo Analysis Task

- From the main menu bar select Task → Direct Simulation → Monto Carlo Analysis.

Define the solver

- Select the Solvers panel.

- For Solver Package Name choose LS-DYNA.

- For Command specify the LS-DYNA executable ls971_R4_2 (This name can be different on your computer).

- For Input File browse the file metal.k.

- For Name of Analysis Case enter SOLVER_1.

- Push the Add button.

Statistical Distribution

- Select the Distribution panel.

- Choose Normal Type.

- For Mean enter 200.

- For Standard Dev enter 20.

- Type in a Distribution Name, e.g. Y.

- Push the Add button.

- Choose Uniform Type.

- For Lower enter 0.6.

- For Upper enter 1.4.

- Type in a Distribution Name, e.g. U_FS.

- Push the Add button.

- Choose Uniform Type.

- For Lower enter 0.

- For Upper enter 50.

- Type in a Distribution Name, e.g. P_OFF.

- Push the Add button.

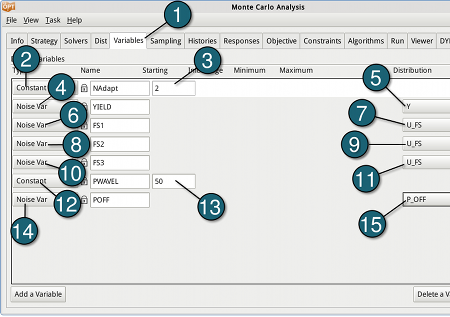

Change Variable

- Select the Variables panel. The variables are already defined in the input file metal.k using *PARAMETER (see below) and therefore cannot be deleted.

- For Type of NAdapt switch the menu to Constant.

Change the (start) value of NAdapt to 2.

- For Type of YIELD switch the menu to Noise Var.

- Choose Y as the Distribution of the variable YIELD.

- For Type of FS1 switch the menu to Noise Var.

- Choose U_FS as the Distribution of the variable FS1.

- For Type of FS2 switch the menu to Noise Var.

- Choose U_FS as the Distribution of the variable FS2.

- For Type of FS3 switch the menu to Noise Var.

- Choose U_FS as the Distribution of the variable FS3.

- For Type of PWAVEL switch the menu to Constant.

- Change the (start) value of PWAVEL to 50.

- For Type of POFF switch the menu to Noise Var.

- Choose P_OFF as the Distribution of the variable POFF.

Sampling Panel

- Select the Sampling Panel.

- For POINT SELECTION choose Latin Hypercube.

- For Number of Simulation Points per Case enter 25.

Define the Responses

Define the maximum percent thinkness reduction

- Select the Responses panel.

- From the possible response types select: D3PLOT.

- For Parts to be included choose All Parts.

- For Result Type select Misc.

- For Component select %_thickness_reduction.

- And select the Maximum Value.

- And the maximum value should be taken from time 0 to the current time.

- For Response Name enter prc_thick_red_max.

- Push the Add button.

Define the FLD

- From the possible response types select: FLD.

- For Parts to be included choose List of Parts.

- In the List of Parts enter 1.

- Push the (Add) > button.

Repeat the previous steps and create this list of parts:

| List of Parts: |

|---|

1 |

| 2 |

| 3 |

- For Sampling locatin select Center surface.

- For Load curve ID enter 90.

- For Response Name enter PLD.

- Push the Add button.

Define the minimum shell thickness

- From the possible response types select: D3PLOT.

- For Parts to be included choose List of Parts.

- In the List of Parts enter 1.

- For Result Type select Misc.

- For Component select shell_thickness.

- And select the Minimum Value.

- And the minimum value should be taken from time 0 to the current time.

- For Response Name enter thick_min.

- Push the Add button.

Define the objective response

- Select the Objective panel.

- From Response select prc_thick_red_max as the objective.

- For Weight leave the default 1. If you have several objective functions, you may assign weight to each one according to their importance.

Define the constraints

- Select the Constraints panel.

- Choose the Response per_thick_red_max as constraint.

- For Lower Bound accept the default -inf.

- For Upper Bound enter 34.

Run panel

- Select the Run panel.

- Push the Run button. (Save the project as com.metal_MC)

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ Command file "com.metal_MC" $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ $ Generated using LS-OPT Version 4.1 $ "Metalforming Analysis Example Problem" $ Author "LS-OPT Class" $ Created on Tue Apr 26 16:29:24 2011 solvers 1 responses 3 $ $ NO HISTORIES ARE DEFINED $ $ $ PROBABILISTIC DISTRIBUTIONS $ distribution 3 distribution 'Y' NORMAL 200 20 distribution 'U_FS' UNIFORM 0.6 1.4 distribution 'P_OFF' UNIFORM 0 50 $ $ DESIGN VARIABLES $ variables 5 Noise variable 'YIELD' distribution 'Y' Noise variable 'FS1' distribution 'U_FS' Noise variable 'POFF' distribution 'P_OFF' Noise variable 'FS2' distribution 'U_FS' Noise variable 'FS3' distribution 'U_FS' $ $ CONSTANTS $ constants 2 Constant 'PWAVEL' 50 Constant 'NAdapt' 2 $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ $ SOLVER "SOLVER_1" $$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$ $ $ DEFINITION OF SOLVER "SOLVER_1" $ solver dyna960 'SOLVER_1' solver command "ls971_R4_2" solver input file "metal.k" solver check output on solver compress d3plot off $ ------ Pre-processor -------- $ NO PREPROCESSOR SPECIFIED $ ------ Post-processor -------- $ NO POSTPROCESSOR SPECIFIED $ ------ Metamodeling --------- solver experiment design lhd_generalized solver number experiments 25 $ ------ Job information ------ solver concurrent jobs 1 $ $ RESPONSES FOR SOLVER "SOLVER_1" $ response 'prc_thick_red_max' 1 0 "D3PlotResponse -res_type misc -cmp %_thickness_reduction -select MAX -start_time 0.0000" response 'FLD' 1 0 "DynaFLDg CENTER 1 2 3 90" response 'thick_min' 1 0 "D3PlotResponse -pids 1 -res_type misc -cmp shell_thickness -select MIN -start_time 0.0000" $ $ OBJECTIVE FUNCTIONS $ objectives 1 objective 'prc_thick_red_max' 1 $ $ CONSTRAINT DEFINITIONS $ constraints 1 constraint 'prc_thick_red_max' upper bound constraint 'prc_thick_red_max' 34 $ $ JOB INFO $ analyze monte carlo STOP