Problem Description

Introduction

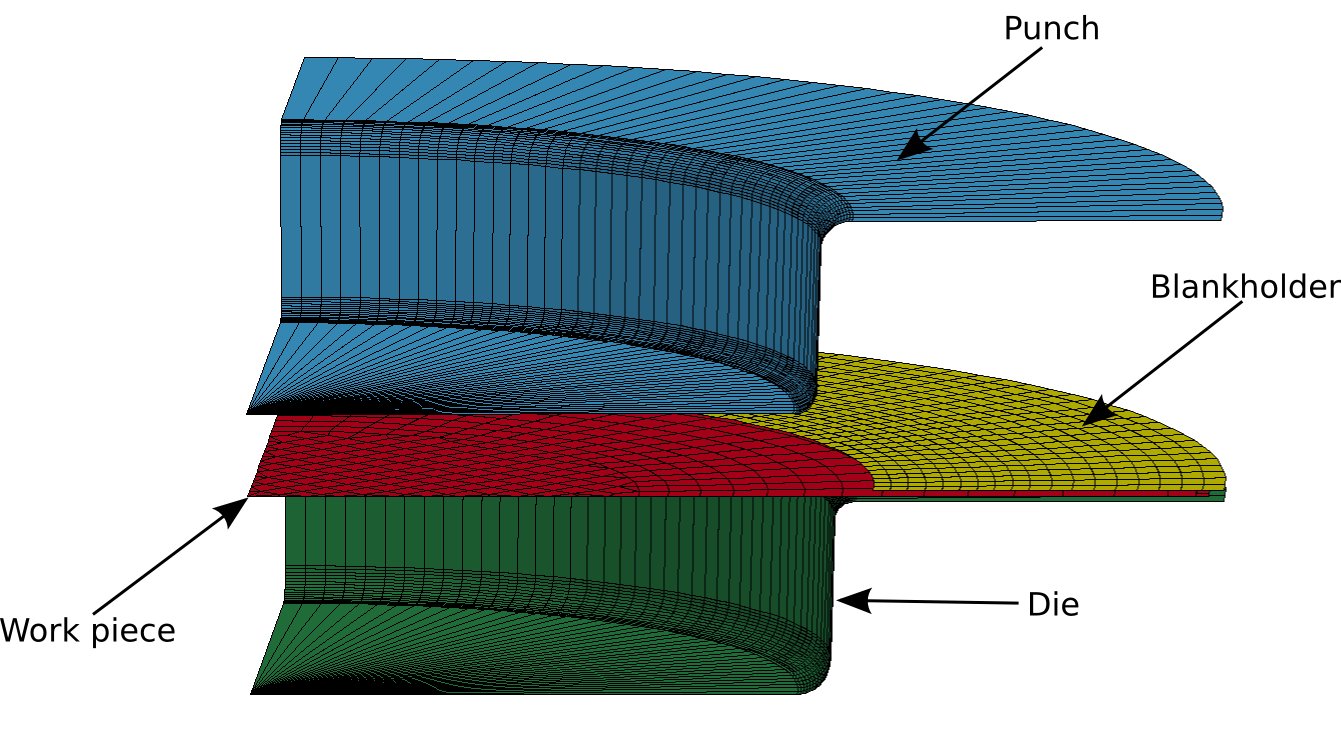

The sheet metal forming process is performed in a two-step procedure. First, a trimming simulation is executed, and in the second step the forming simulation is performed. Adaptive meshing is used in the finite element analysis. Both simulations are run with LS-DYNA.

Metamodel-based Monte Carlo Analysis

A metamodel-based Monte Carlo Analysis is performed to judge on the robustness of the model. Uncertainties of parameters are incorporated by assigning a statistical distribution to each design variable. The results are statistics of the variation of the system responses caused by the variation of the parameters.

Design Variables

- The force applied by the punch → f_force

- The scale factor for the load curve to define the material hardening parameter → SCALE

- The statical coefficient of friction between the work piece and the blankholder → FRIC

Responses

- Upper surface of the Forming Limit Diagram → FLD_upper_surface

- Lower surface of the Forming Limit Diagram → FLD_lower_surface

- Center surface of the Forming Limit Diagram → FLD_center_surface

- Maximum thickness reduction of the work piece → THICKNESS

Problem Solution