Problem Description

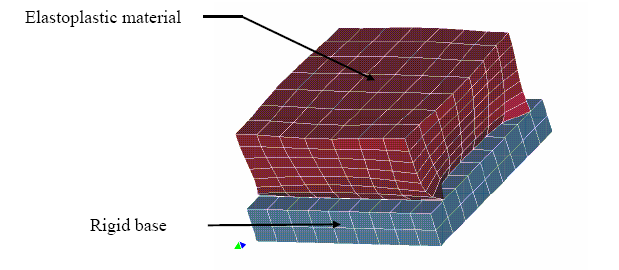

The material parameters of a foam material must be determined from experimental results, namely the resultant reaction force exerted by a cubic sample on a rigid base.

Fig. 1 - Foam material on rigid base

The ''experimental'' resultant forces were generated from a LS-DYNA run with the parameters E=10⁶ and Y=10³. Samples are taken at different time steps :

| Time [ms] | Force [N] |

| 2 | 10000 |

| 4 | 13000 |

| 6 | 15000 |

| 8 | 17000 |

New points illustrated by this example:

|

Design Variables:

Design formulation:

|

Possible approaches for the problem solution |

Downloads |